Production of prefabricated concrete parts is one of the most widely used technologies in the construction industry of buildings, bridges, tunnels, etc. In the case of prefabricated buildings, in addition to having sufficient strength, they should also be as light as possible to reduce the dead load weight of the structure (building) so as not to adversely affect the performance of the structure against the lateral force of the earthquake.

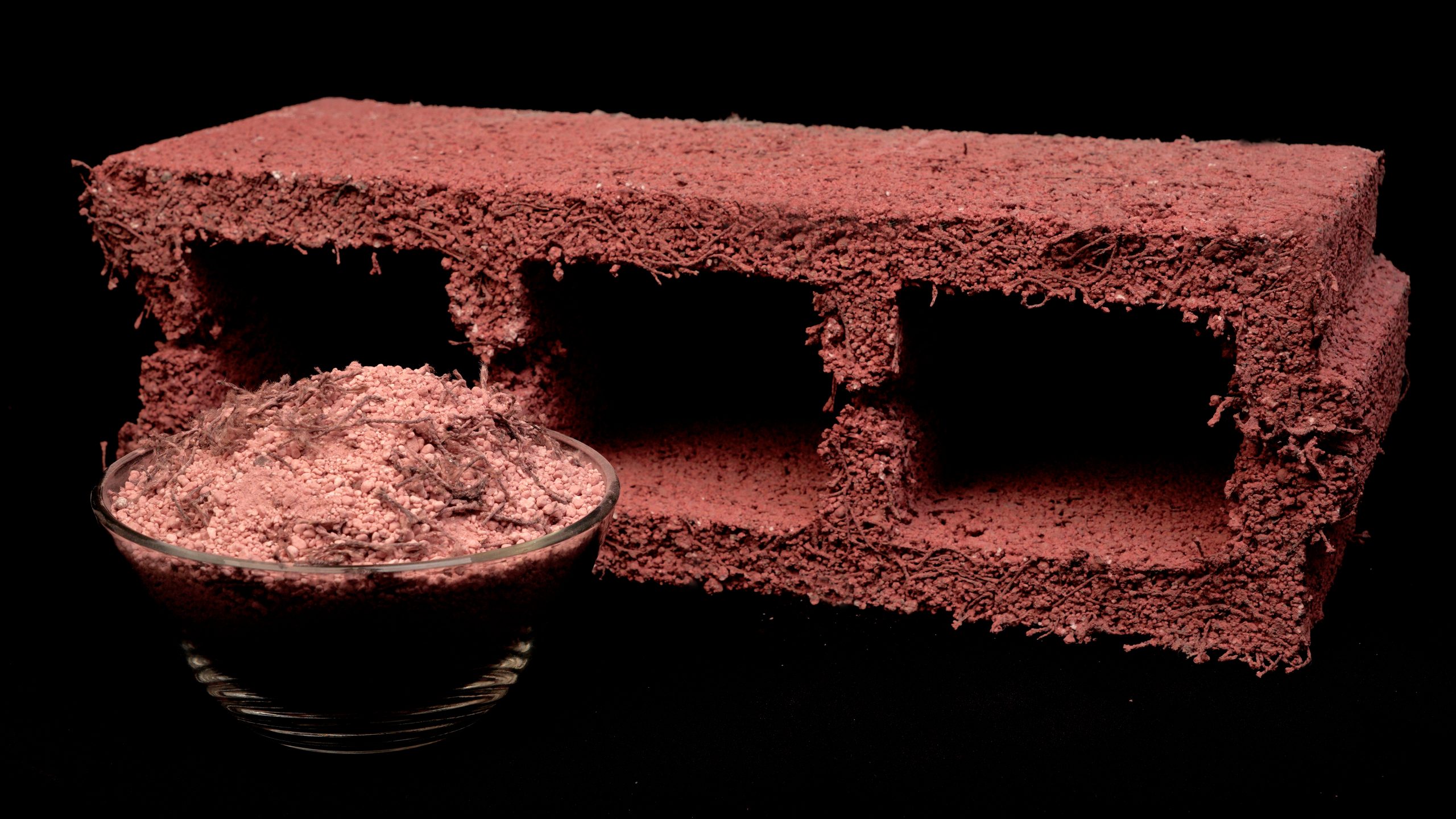

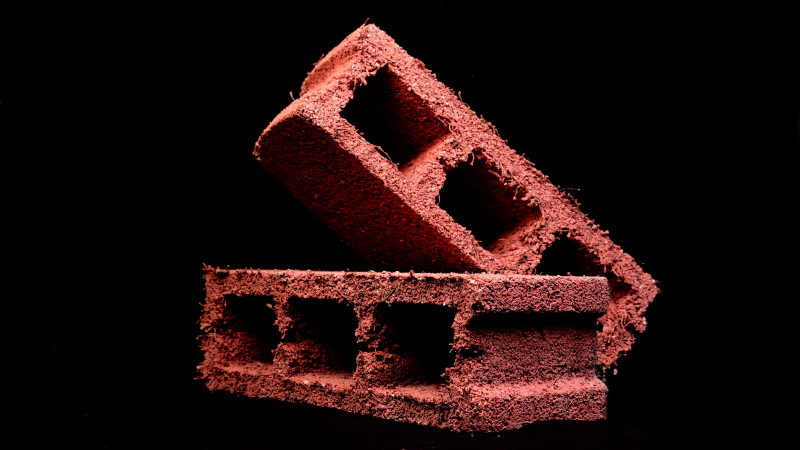

Laboratory study of mechanical properties of Ras non-structural lightweight concrete composite raw materials Due to other available lightweight concrete materials, the mechanical properties of Ras lightweight concrete have been significantly improved and for compression, Brazilian tensile and 4-point flexural tests. The results show that with the addition of composite and processed materials of the production and industrial group of Ras, the tensile strength increased by 23.1%. The flexural strength also shows an increase of 28.9%. The composite material had a very small adverse effect (about 7%) on the compressive strength of the specimens, which will not be so problematic due to the non-structural light production concrete.

Lightweight concrete can play an important role in the production of prefabricated building parts and in addition to reducing construction time, can significantly reduce the weight of the building. And improve the performance of the structure against the lateral force of earthquake and wind. To make lightweight concrete, low-volume aggregates should be used. Lightweight concrete, like ordinary concrete, has several weaknesses in its mechanical properties that can be eliminated by using these composite materials, which in addition to not increasing the specific gravity of concrete is also economically viable and can be the mechanical properties of concrete. Upgrade the style to a considerable extent.

Another point

Regarding the mechanical properties of fiber reinforced concrete of Ras Production and Industrial Group, the effect of PA polyamide fibers on flexural responses according to ASTM standards has been investigated. And the results were that polyamide fibers are more useful than other fibers because they are not corrosive and also significantly improve the hardness and ductility of concrete. Another important result is that the flexural strength and impact resistance increased with the presence of fibers and the melting and frost resistance test was performed for the apex concrete and the results showed that the other concretes were destroyed before the end of the test and the sample The tops of the concrete showed a slight weight change and the concrete increased the resistance to melting and frost of the concrete by creating intentional air bubbles and also the abrasion resistance of the concrete increased by adding fibers.